PACVision C - McKesson Canada

Capability to capture a colour image of a corrected pouch means all verified pouches can be documented without exception

Immune to distractions or fatigue, ensuring that pouches are verified consistently, quickly and securely

Minimizes pharmacist intervention, freeing up time for patient counselling and other responsibilities

High precision colour recognition method unique to each site

Capability to capture a colour image of a corrected pouch means all verified pouches can be documented without exception

Immune to distractions or fatigue, ensuring that pouches are verified consistently, quickly and securely

Minimizes pharmacist intervention, freeing up time for patient counselling and other responsibilities

High precision colour recognition method unique to each site

Increased accuracy

-

Colour recognition accuracy is ensured with our unique high-precision method that takes the environmental characteristics of your site into consideration.

-

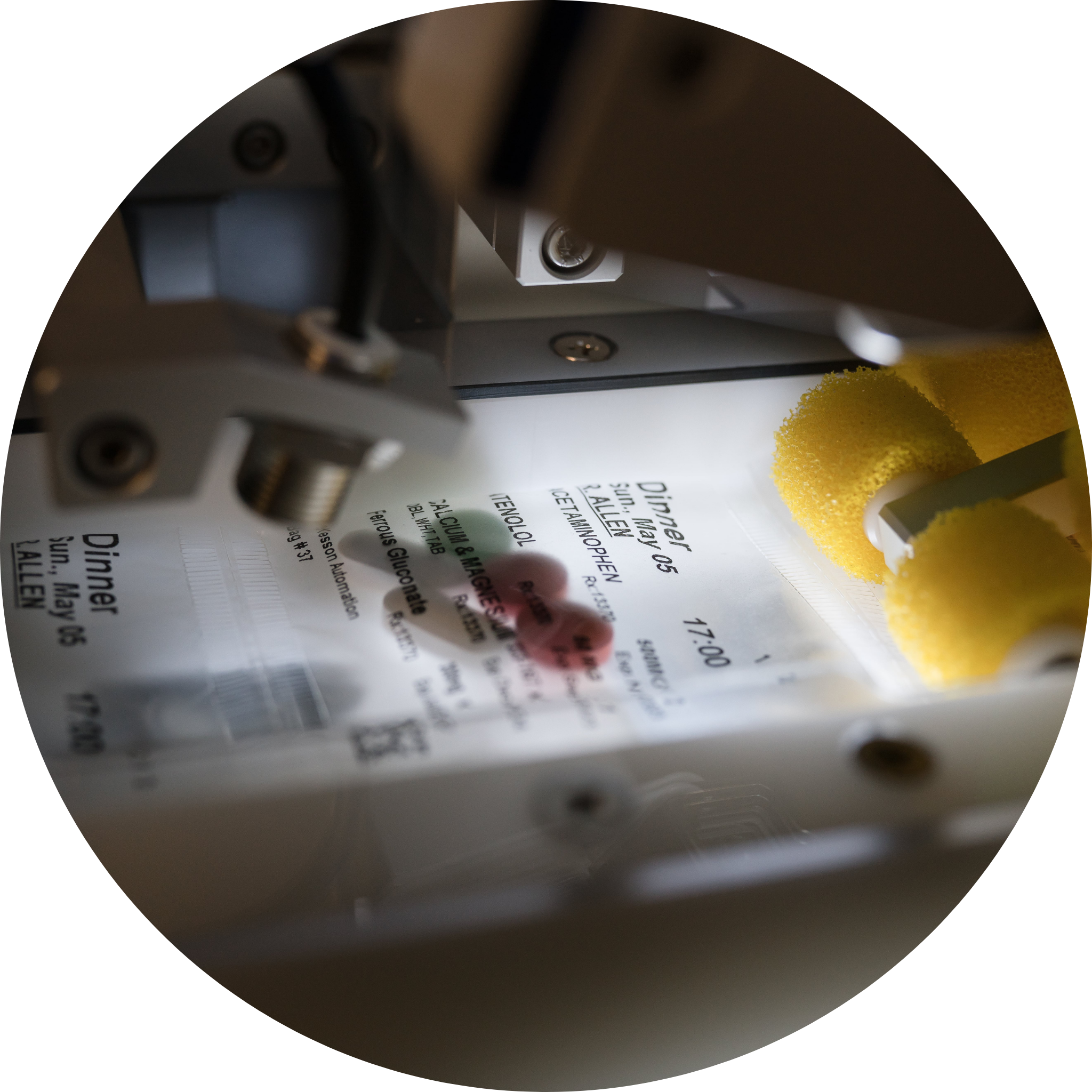

Using an advanced pill recognition system, PACVision verifies every pouch for pill quantity, colour, size and shape.

-

Assurance that every dose is checked and that any discrepancies are flagged.

Safety

-

User-friendly interface allows for easy search and retrieval of all pouch images for traceability.

-

All verified pouches can be documented without exception. Immune to distractions or fatigue, PACVision C verifies pouches consistently, quickly and securely.

Increased accuracy

Productivity

Safety

PACVision C FAQ

What is PACVision C and how does it differ from the standard PACVision inspection unit?

PACVision C is a compact inspection solution built for small to medium-scale pharmacy or central-fill operations. It delivers the same advanced color-recognition and pill-verification technology as PACVision, but in a streamlined design optimized for lower-volume environments.

How does PACVision C verify pouch packaging and what features ensure accuracy and traceability?

PACVision C verifies each pouch from a PACMED line in less than a second - checking pill quantity, color, size, and shape with precision. It also captures a color image of every pouch for easy archival retrieval, supporting full traceability and helping reduce the risk of human error.

Which size of operation is best suited for PACVision C rather than the full-scale model?

PACVision C is purpose-built for small to medium-scale operations, whether that’s a pharmacy, a multi-site provincial chain, or a packaging hub with moderate throughput. If your volume is lower and space or budget are key considerations, PACVision C delivers the full inspection technology of PACVision in a compact, cost-efficient design.

From a productivity standpoint, how does PACVision C integrate with PACMED lines?

PACVision C integrates fully with PACMED packaging lines. A single unit can support multiple PACMED machines and validation workstations, streamlining packaging and verification workflows—without adding to the manual checking burden.

What cost-and-benefit factors should procurement or finance teams evaluate when considering PACVision C?

Key factors to consider include reduced manual inspection labor, fewer packaging errors that help minimize waste and returns, improved traceability for patient safety that lowers liability risk, and a smaller footprint that reduces installation costs. These benefits should be weighed against upfront capital investment, integration and training requirements, and ongoing maintenance.

How does PACVision C compare with manual visual verification or semi-automated inspection systems in terms of error risk and efficiency?

Compared to manual visual checks, PACVision C delivers consistent verification that is immune to fatigue, reducing the risk of human error and increasing throughput per pouch. Compared to semi-automated systems, PACVision C provides full automation of inspection with integrated imaging and archival, improving accuracy and traceability.

What infrastructure or installation requirements should an operation plan for when deploying PACVision C?

You should plan for sufficient bench or floor space appropriate for small to medium-scale operations, network connectivity for image archiving and retrieval, integration with existing PACMED packaging lines, operator training for the validation interface, and workflow adjustments to align packaging, inspection, and traceability.

How does PACVision C support compliance, audit trails and documentation for pouch-packaging inspection?

PACVision C captures a color image of every verified pouch, stores those images for easy retrieval, automatically flags any discrepancies, and records inspection metadata. These capabilities create strong audit trails and comprehensive documentation to support regulatory compliance and internal quality assurance.

What measurable improvements or outcomes might a pharmacy expect after implementing PACVision C?

PACVision C verifies each pouch in less than a second and minimizes pharmacist intervention, freeing time for patient counseling. These advantages translate into higher throughput, reduced inspection labor, fewer errors, and greater pharmacist availability for patient care.

How should a pharmacy or packaging operation decide between PACVision C and the full-scale PACVision model?

Your decision should be guided by throughput volume, available space, budget, and the level of automation you want to achieve. For small to medium-volume operations with limited space that still require the same core inspection technology, PACVision C is an excellent fit. For large-volume packaging demands with multiple PACMED lines, the standard PACVision may be the better choice.