PACVision - McKesson Canada

High precision colour recognition method unique to each site

Industry-proven algorithm for pill verification

Engineered to meet the needs of a large-scale operation, its compact size ensures easy integration into your workflow

PACVision verifies pouches consistently, quickly and securely

High precision colour recognition method unique to each site

Industry-proven algorithm for pill verification

Engineered to meet the needs of a large-scale operation, its compact size ensures easy integration into your workflow

PACVision verifies pouches consistently, quickly and securely

Brief Overview

Increased accuracy

-

Colour recognition accuracy is ensured with our unique high-precision method that takes the environmental characteristics of your site into consideration.

-

Using an advanced pill recognition system, PACVision verifies every pouch for pill quantity, colour, size and shape.

-

Assurance that every dose is checked and that any discrepancies are flagged.

Safety

-

User-friendly interface allows for easy search and retrieval of all pouch images for traceability.

-

All verified pouches can be documented without exception.

-

Immune to distractions or fatigue, PACVision verifies pouches consistently, quickly and securely.

Increased accuracy

Productivity

Safety

PACVision FAQ

What is PACVision and how does it improve pouch-packaging verification in pharmacy automation?

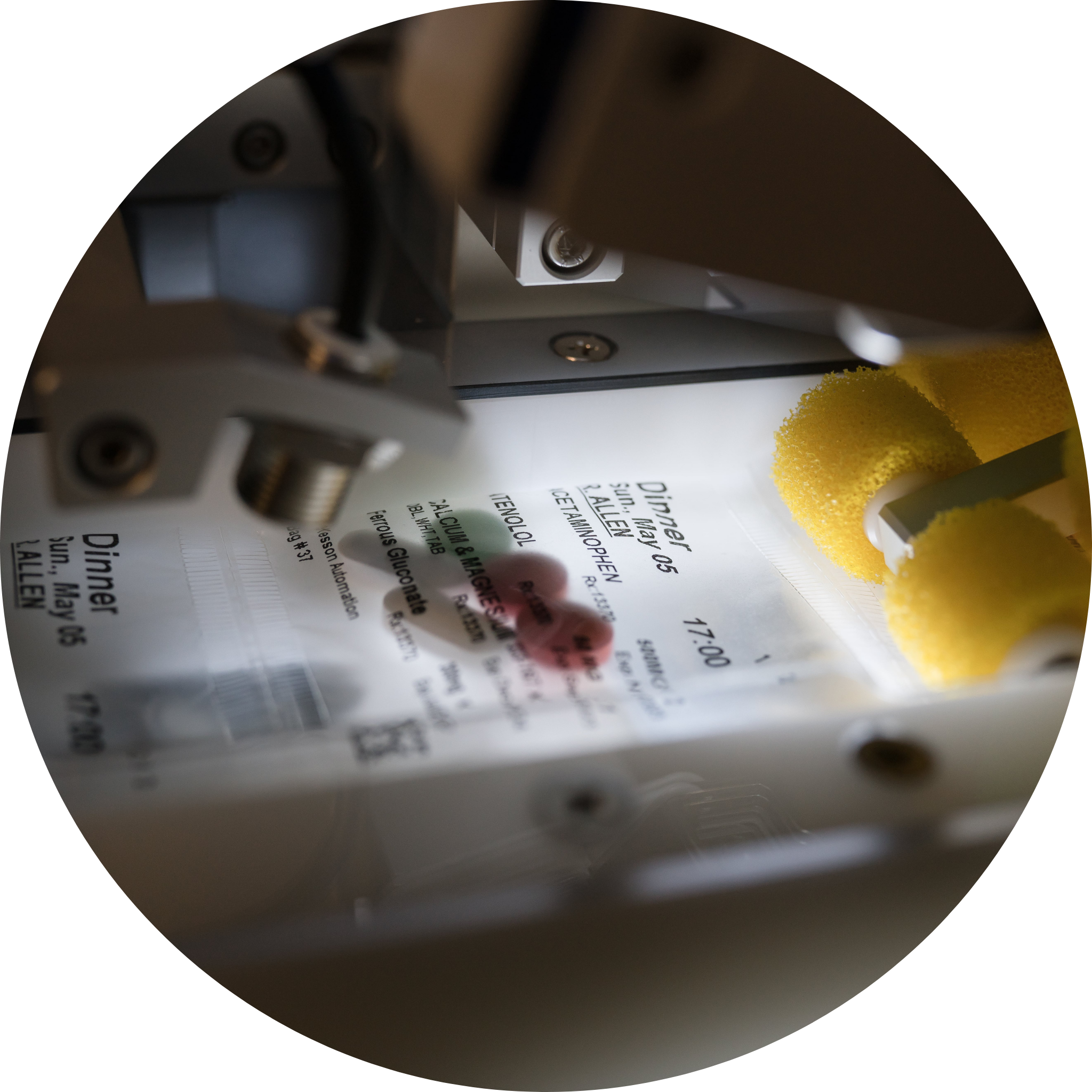

PACVision is an inspection unit designed for large-scale pharmacy and central-fill operations. It verifies each pouch from the PACMED™ system for pill quantity, color, size, and shape in under one second—enhancing accuracy and safety throughout the pouch-packaging workflow.

How does PACVision detect errors in pouch packaging, and what features support traceability?

PACVision uses a high-precision color-recognition method unique to each site and an industry-proven algorithm for pill verification. It captures color images of every verified pouch for archiving and retrieval—enabling complete documentation and trace-audit of each dose.

What kind of throughput or speed can PACVision handle in a high-volume operation?

PACVision is designed to verify each PACMED pouch in less than one second—a key benefit that ensures high throughput and makes it ideal for large-scale pharmacy and central-fill environments.

Which workflows or operations are best suited for PACVision — retail pharmacy, long-term care, or central-fill?

PACVision is designed for large-scale operations such as central-fill or high-volume packaging centers that already use PACMED pouch packaging and need fast, automated verification. For smaller operations, the PACVision Model C variant may be a better fit.

From a procurement or finance perspective, what cost-benefit factors should I evaluate when considering PACVision?

PACVision delivers benefits such as reduced manual inspection labor, fewer dispensing or packaging errors (lowering waste and liability), increased packaging throughput, and seamless integration with PACMED systems to avoid duplicate investments. These advantages should be weighed against footprint requirements, integration costs, and staff training.

How does PACVision compare with manual visual inspection or semi-automated systems in terms of error-risk and productivity?

Compared to manual inspection, PACVision delivers consistent, rapid verification that’s immune to distractions or fatigue, helping reduce the risk of human error. Designed for efficiency, PACVision also drives productivity by seamlessly integrating with multiple PACMED systems or validated workstations.

What installation or integration requirements should a pharmacy plan for when deploying PACVision?

Planning ahead is essential. Consider space requirements for the unit, connectivity with your PACMED or pouch-packaging system, user interface and training for image retrieval and archiving, software integration to ensure traceability, and workflow alignment to maintain inspection throughput.

What measurable improvements (error reduction, throughput, verification time) have clients reported after using PACVision?

Customers consistently report meaningful improvements with PACVision. One pharmacy shared: “In a busy pharmacy, speed and accuracy are vital. Using PACVision helps our dispensary run more smoothly without compromising patient safety.

How does PACVision support regulatory compliance, auditability and documentation of pouch-packaging verification?

By capturing color images of every verified pouch, maintaining a searchable archive, and ensuring consistent dose verification, PACVision strengthens traceability, supports audit reviews, and documents packaging accuracy to help meet compliance requirements.

What variant options exist for PACVision and how should I choose between models (e.g., large-scale vs small-to-medium-scale deployment)?

PACVision is designed for large-scale operations, while PACVision C brings the same core technology in a smaller footprint and at a lower cost, ideal for small to medium-scale pharmacies. The right choice depends on your volume, available space, and budget.